EQUIPMENT > CEMENT STORAGE UNITS, CEMENT PUMPS

CEMENT BULK STORAGE - SILO FOR CEMENT ACCUMULATION AND STORAGE

We offer bulk storages (silos) for cement (gypsum, lime, mineral powder and so on) of 12 - 100 m3 (cub.m) capacity.

Cement silos are intended for receiving cement or other products from bulk cement transport vehicles, storing and delivery of cement to consumers, or its transportation to metering units.

BASIC DIAGRAM OF CEMENT STORAGE SILO

Cement silo is a welded metallic structure in cylindrical form, with conical bottom.

Silo is equipped with pipeline for cement delivery from the bulk cement transport vehicle, as well as manhole, relief valve (upon request of the Customer) which is activated in case of pressure increase inside the silo, welded ladder, aeration unit, electric or pneumatic vibrators, cement level gages, cement filters, service staff platform and other structures and devices.

Cement silo is mounted on the carrier unit of prefabricated construction. Carrier unit comprises vertical supporting pillars made of pipes and traverse beams of angle sections. Supporting pillars and traverse beams are connected using bolts.

Cement storage tank is fastened on the carrier unit with the use of bolt clamping. Carrier unit in its lower part is fixed on the foundation, by means of foundation bolts. Metallic silo for cement is produced taking into consideration of all the relevant technical requirements.

Upon request of the Customer, silos can be completed with safety system including:

- cement filter,

- level gages with controller,

- relief valves,

- pneumatic vibrators,

- electric vibrators,

- pneumatic guns,

- oscillating ventilators,

- aeration nozzles,

- bottom vibrators,

- butterfly gates.

Pneumatic chamber pumps for pumping of cement - cement reloading solution

We offer offers pneumatic chamber pumps for pumping of cement, of capacity up to 50 t /hour (unloading of cement silos, hopper cars).

Pneumatic chamber pump is intended for vertical and horizontal transportation of cement and other dust-like materials through pipelines using compressed air at the enterprises of cement industry, mining, metallurgical, chemical industry, as well as enterprises producing lime, gypsum, refractory and other materials. Delivery of pump: vertical - up to 30 m, horizontal - up to 200 m.

It is completed with oil-and-moisture separator, electric valve, control panel, gates.

PRICES FOR BULK STORAGES (SILOS) OF CEMENT AND COMPONENTS

| № | Name | Volume, м3 |

Weight, for cement (1400 kg/m3), t | Price, USD, VAT excluded | |

| 1 | СЦ-12 | 12,0 | 16,8 | with request | |

| 2 | СЦ-30 | 30,0 | 42,0 | with request | |

| 3 | СЦ-50 | 50,0 | 70,0 | with request | |

| 4 | СЦ-85 | 85,0 | 119,5 | with request | |

| 5 | СЦ-100 | 100,0 | 140,0 | with request | |

| 6 | Cement filter | - | - | with request | |

| 7 | Pneumatic chamber pump ПКНЦ-50 | 1,0 | - | with request | |

Cement silo delivery period is 1 - 2 months; it depends on the load of production facilities.

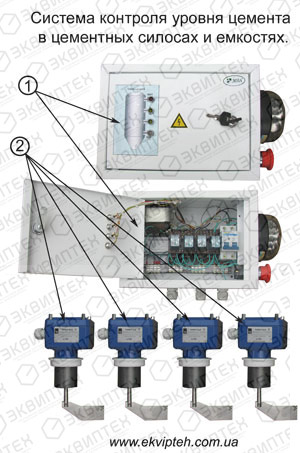

System for controlling the level of material (cement) in the silo.

"EKVIPTEH" LLC produces the system for recording and controlling the level of materials of any degree of complexity. Recording of the level of consumption and availability of material in silos and bins of cement (other materials) allows obtaining of operative information about the current status of silos (their fullness or emptiness) on remote basis.

All of this allows the Customer to fill up silos operatively, to predict consumption of materials, and to organize obtaining of incoming materials in due time.

System for recording the level of material consists of two basic elements (see Figure):

- 1 - Material level control panel,

- 2 - Rotary-paddle (or other) sensors - level indicators.

The level gages are used for monitoring of the level in containers and bins of any kind. They can be used for any powdered, granular and bulk materials, featuring no noticeable tendency to formation of crust or sediments. Wide range of use was also shown regarding production of foodstuffs.

Rotary paddle level indicators ILТ are intended for indication of maximum or minimum level of material in the collecting tank, bin or silo, with the use of rotary movement.

Level controller panel reflects the current status of each sensor with audio signal of emptying or overfilling of the silo.

Average time of the order fulfillment - 2 weeks.

REFERENCE INFORMATION

PROPERTIES OF PORTLAND CEMENT

Portland cement is one of the most important hydraulic binding material, which is widely used in construction industry. Portland cement is the product of fine grinding of cement clinker, which is obtained by firing till agglomeration of artificial mixture (limestone, chalk stone, clay etc.) or natural raw materials of appropriate composition, ensuring prevalence of calcium silicates in cement. During grinding of clinker, the additives mentioned below are introduced: 1.5-3.5% of gypsum (in terms of anhydride of sulfuric acid SO3) for regulation of setting time, up to 15% of active mineral additives - for improvement of certain properties and reduction of cement cost.

Basic technical properties of portland cement include: density and bulk weight, fineness of grind, setting time, soundness of cement grout and strength of hardened cement mortar.

Density of cement varies in the range of 3.0-3.2 g/cm3, bulk weight in loose condition is 900-1100 kg/m3 and up to 1700 kg/m3 in compacted condition.

Fineness of grind is characterizing the degree of cement fineness, and it is determined by sieve analysis (screening with the use of specified sieves). More exact characteristic of the degree of cement fineness is its specific surface area, i.e. surface of all grains contained in 1 g of cement. Fineness of grind has significant influence on strength of cement stone. The finer is cement (within specified limits), the higher is strength of cement stone.

According to the requirements of GOST 10178-62, fineness of grind should ensure that not less than 85% of all weighed portion of portland cement pass through sieve No. 008.

Specific surface area of ordinary portland cement is within limits of 2000-3000 cm2/g and 3000-5000 cm2/g for quick-hardening cement and high-strength cement.

Time of setting of cement grout (cement + water) depends on fineness of grind, mineral composition and water requirement of cement. In such a case, water requirement is characterized by water amount in percent of cement weight required for obtaining the grout of normal consistency, i.e. definite flowability (24-28%).

According to the said GOST, beginning of setting should occur not earlier than in 45 minutes, and setting is to be completed in 12 hours at most. Beginning of setting is understood as the time elapsed from the start of cement mixing with water till start of thickening of cement grout; completion of setting shall be the time interval from the beginning of cement grouting till complete loss of cement plasticity.

With the increase in temperature, setting of cement grout is speeded up, and with temperature decrease it slows down. Setting, which is completed in the relatively short term (several hours), is followed by long-term process of transformation of cement grout into cement rock.